burst test tyvek seal strength flexible package|package seal strength testing : makers Validation data on preformed sterile barrier systems. Responsibilities – Medical Device Manufacture. All seals on Form Fill Seal (FFS) Final seal on purchased pouches. Final . 6 de jan. de 2024 · Teste Dos 8 Valores Reprodutibilidade e valor diagnostico de testes quantitativos no diabetes mellitus Suzana Alves de Moraes 1990 Com o objetivo de avaliar um teste simplificado para o diagnostico do diabetes mellitus, estudamos por 4 dias consecutivos, 20 individuos (12 normais e 8 diabeticos) com idade entre 20 e 59 anos.

{plog:ftitle_list}

WEB18 de dez. de 2023 · Peça pratos da cozinha Brasileira neste pub & bar. Coma feijoada fascinante no pub & bar Casa da Mãe Joana quando estiver por perto. O serviço pronto é algo que visitantes mencionam nas avaliações. O ambiente deste lugar é calmo. 4.5 é o que este pub & bar ganhou do sistema de avaliação do Google.

seal strength testing

back scratch test procedure

ASTM F88 Standard Test Method for Seal Strength of Flexible Barrier Materials addresses opening force, package integrity, and the ability to produce consistent seals.Validation data on preformed sterile barrier systems. Responsibilities – Medical Device Manufacture. All seals on Form Fill Seal (FFS) Final seal on purchased pouches. Final .ASTM F1140 burst strength testing helps to determine the ability of an open or closed package to withstand internal pressurization. The peel and burst tests are the most commonly used methods for measuring the seal strength of peelable flexible packages. The peel test measures the force required to peel .

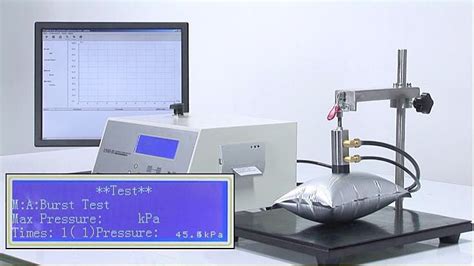

Inflation seal-strength testing (ASTM F1140 and ASTM F2054) includes burst, creep, and creep-to-failure testing. Burst testing pressurizes the entire package and captures .

Failures can also occur during the three main tests for package strength: seal peel, burst, and creep: • Seal Peel. Seal peel failures are generally very similar to those of the dye migration test.Both methods are suitable for measuring seal strength. ASTM standards provide for several test methods for burst testing, including dynamic, static, creep, and creep to fail tests. These tests are used to measure the strength of medical . In this blog, we will explain how other processes, like a Design of Experiments, help us determine the optimal seal strength for sterile barrier packaging. When we are testing for seal strength, what are we measuring . The Role of Seal Strength Testing in Different Industries. Pharmaceuticals Regulatory Compliance: Seal strength testing ensures that pharmaceutical packaging meets stringent regulatory requirements, including those set by the FDA and other international bodies. Compliance with these regulations is essential for ensuring the safety and efficacy .

Geoff, when I first started on flexible packaging in the early 1990's, we were using the ARO book which provided minimum burst values for different types of pouches/bags designs and it was based .

The Pouch Burst Tester is used to test the maximum internal pressure a pouch can withstand without the seals or the body rupturing. This test can be considered as a full seal integrity / seal strength test of a formed pouch. The weakest portion of the pouch can be quickly and easily detected. And you can differentiate between a Weak Seal pouch and a Weak Laminate pouch.This property indicates how a package will perform if an object falls on the package or if an object in the package strikes the lid. DuPont uses procedure B of ASTM D3420, modified with a 9/16-in. (14.28-mm) diameter hemispheric-shaped probe tip with a 6,400-gram pendulum, which is necessary to puncture tough materials like Tyvek®.An indicator of the minimum burst strength may be of importance to the package manufacturer and end user in ensuring adequate package integrity. This test method cannot provide a measure of package seal uniformity. This test method also cannot provide an evaluation of overall package integrity or the burst strength of areas of the package that

seal burst strength testing

A packaging seal strength test is used to measures the strength of the seals in the packaging material to prevent the package from opening during handling and transportation. Seal strength is typically measured in terms of force required to open or peel apart the sealed layers. . This includes pouches and trays with flexible lids. Burst .One of the tests applied to the food packaging product will be seal strength test. In this test, the amount of pressure is being gauged in order to separate the sealed pieces of the packaging. There are a lot of methodologies in order to ascertain the packaging seal strength. Tensile peel test and burst test are widely used for this purpose. Seal strength also ensures control of the peel. ISO 11607 addresses two types of seal-strength testing: tensile strength testing and burst or creep testing. Pull it apart. Tensile seal-strength testing (ASTM F88) uses a defined width sample (25.4 mm or 1 in.) of the package seal perimeter. All: please keep in mind that burst testing and peel testing will not ensure package integrity for tyvek, as these methods only give an indication of seal-strength. These test methods will NOT detect pinholes in the top or bottom webs of the material. An additional test method that may be considered here is an underwater-leak test.

The burst test identifies the pressure at which the weakest seal will burst. This is not a pass or fail test; it simply sets the burst pressure benchmark for the packaging. The creep test can then be conducted by inflating the sealed package to 80 percent of the burst test benchmark and measuring the length of time or ‘creep’ until package .

ASTM F1140 (aka “burst testing”) is another common test that measures seal strength by internally pressurizing a sterile barrier system until it ruptures (a package inflates like a balloon until it pops). The amount of internal pressure at rupture is recorded. . Seal strength testing allows packaging engineers to design packages with .It is necessary to test the seal burst strength of a package to ensure the product remains sterile and protected. . materials such as medical-grade paper and Tyvek®1 which allow penetration of sterilant but not microorganisms, and provide . ASTM F88 Standard Test Method for Seal Strength of Flexible Barrier Materials addresses opening .

Inflation seal-strength testing (ASTM F1140 and ASTM F2054) includes burst, creep, and creep-to-failure testing. Burst testing pressurizes the entire package and captures the peak rupture pressure. This test provides a whole-package minimum seal strength, and is equally applicable to peelable and nonpeelable seals.Package burst tester for F1140 test which is the creep and burst test, package seal strength. Integrity tester by using compressed air leak test, for burst strength test. . Seal strength and leak integrity test device for medical flexible packaging such as Tyvek™ and foil bags - Quick Pouch Tester .Keystone has a full lab of test equipment which permits us to provide short lead times on scheduling. Our team strives to give our customers more time and energy on product development instead of testing. We can accommodate flexible and rigid packages of all sizes, including large pallets. In addition to ASTM F1140 testing, Keystone has a full scope of . ASTM Test Method F2054-00 (2005) “Standard Test Method for Burst Testing of Flexible Packaging Seals Using Internal Pressurization within Restraining Plates” Post-sterile Inspection: Once you have established that your test criterion meets the requirements of these standards, we can address your post-sterile inspection question.

Seal strength test methods evaluate the integrity of seals on various types of packaging, from food containers to medical supplies. . Identifies weak points in the packaging design; Burst testing is particularly useful for assessing the integrity of flexible packaging materials used in medical device sterilization pouches. F17 Terminology Relating to Primary Barrier Packaging F2824 Test Method for Mechanical Seal StrengthTesting for Round Cups and Bowl Containers with Flexible Peelable Lids F3263 Guide for Packaging Test Method Validation 3. Terminology 3.1 De®nitions: 3.1.1 average seal strength, nÐaverage force per unit width

Summary Chart: Seven Seal Testing Methods for Flexible Packaging. This summary chart will help you compare all seven seal tests for flexible packaging on your flow wrappers and vertical FFS baggers. If you’d like help defining your sealing objectives and evaluating seal testing methods, contact Greener Corporation. We provide package quality . F904 Test Method for Comparison of Bond Strength or Ply Adhesion of Similar Laminates Made from Flexible Ma-terials F2824 Test Method for Mechanical Seal StrengthTesting for Round Cups and Bowl Containers with Flexible Peelable Lids 3. Terminology 3.1 DeÞnitions: 3.1.1 average seal strength, nÑ average force per unit width It cannot be assumed that the seal which fails first under burst test is the “weakest” seal on the package, due to how significant package geometry is to the burst test itself. It is entirely possible that the seal which ruptures in the burst is found to be stronger than an adjacent seal located in a different position of the package if .It is necessary to test the seal burst strength of a package to ensure the product remains sterile and protected. . materials such as medical-grade paper and Tyvek®1 which allow penetration of sterilant but not microorganisms, and provide . ASTM F88 Standard Test Method for Seal Strength of Flexible Barrier Materials addresses opening .

ความดันที่ทำให้ถุงฉีกขาด (burst pressure) คือการทดสอบทางอ้อมของความแข็งแรงของซีล (seal strength) โดยรวม คนส่วนใหญ่มักจะตัดตัวอย่างจากส่วน . Standard Test Method for Seal Strength of Flexible Barrier Materials — F88/F88M-21; Standard Test Method for Mechanical Seal Strength Testing for Round Cups and Bowl Containers with Flexible Peelable Lids — F2824-10(2020) All forms of packaging in which a seal must be removed to access the product; Advantages of Seal Strength Testing An indicator of the minimum burst strength may be of importance to the package manufacturer and end user in ensuring adequate package integrity. This test method cannot provide a measure of package seal uniformity. This test method also cannot provide an evaluation of overall package integrity or the burst strength of areas of the package that

Load a random cam within thousands of free live sex cams. L.

burst test tyvek seal strength flexible package|package seal strength testing